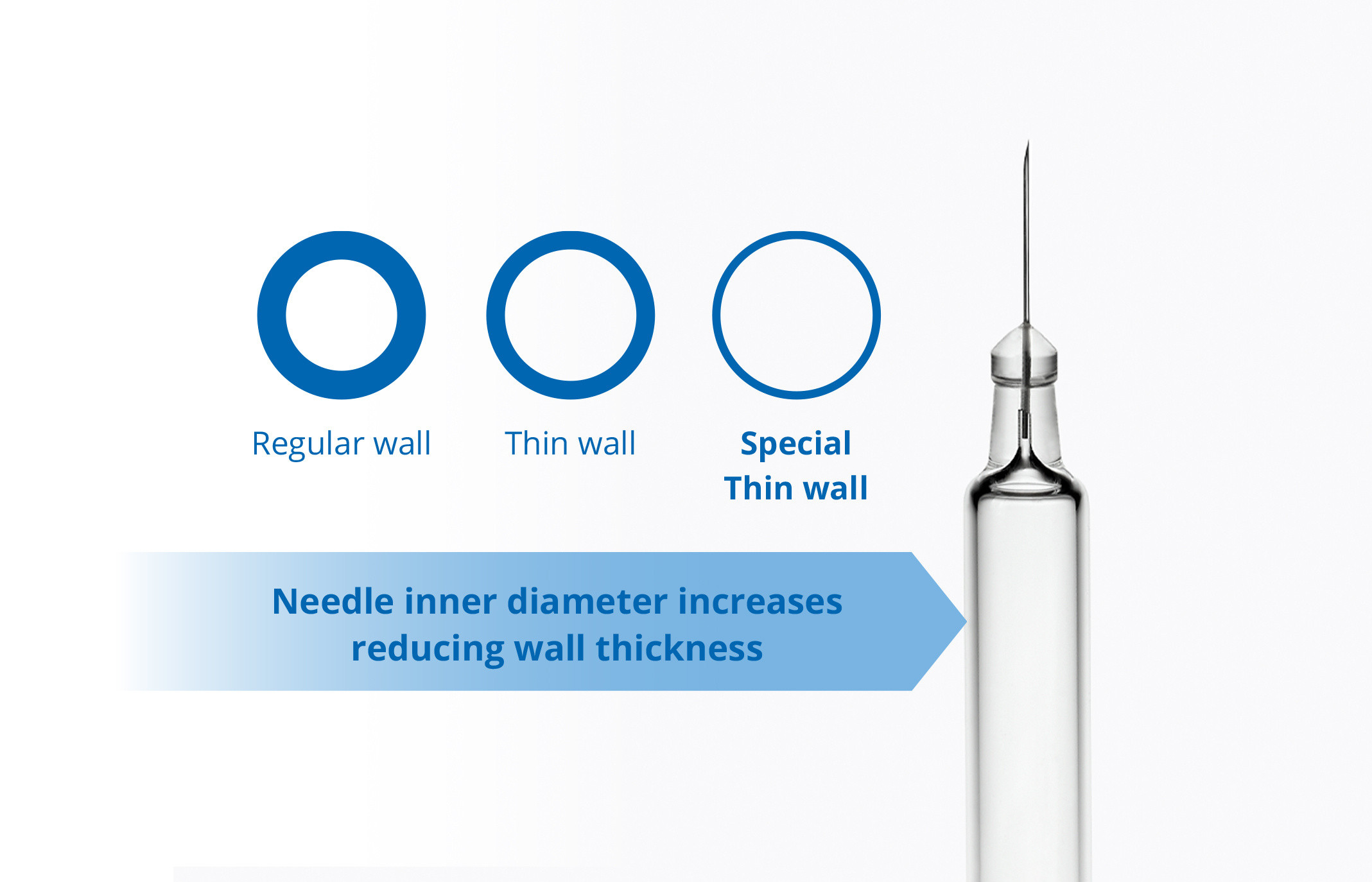

As injectable drugs evolve, the challenge of delivering high-viscosity or high-volume formulations grows, requiring careful consideration of patient comfort. Our Special Thin-Wall (sTW) needle features an enlarged internal diameter to optimize the delivery of highly viscous drug formulations without the need for larger needles, meeting auto-injector device requirements and enhancing the overall patient experience.

Available in 25, 27 and 29 gauge, the ½” needle with five-bevels tip is manufactured with AISI 304 stainless steel and has been designed to meet the requirements of Nexa® and Alba® performance levels in terms of dimension, cosmetics, penetration, and breakage resistance. sTW Needles are currently applicable to 1ml long and 2.25ml syringe formats. Our sTW needle is available in both the traditional 12.7mm length and the innovative 8mm length. This design further reduces the frictional potential of the needle, thereby decreasing the required injection force. Laboratory evaluations of break-loose extrusion have been conducted to confirm the reduced injection force.

| NEEDLE CONFIGURATION IN DIFFERENT VISCOSITIES (cP) | |||

|---|---|---|---|

| Needle Length |

12,7mm |

8mm |

|

| Gauge |

Special-TW |

TW |

Special-TW |

| 25G | > 30 cP | ||

| 27G | 10 – 30 cP | ≤ 15 cP | > 15 cP |

| 29G | ≤ 10 cP | ||

Product in Portfolio

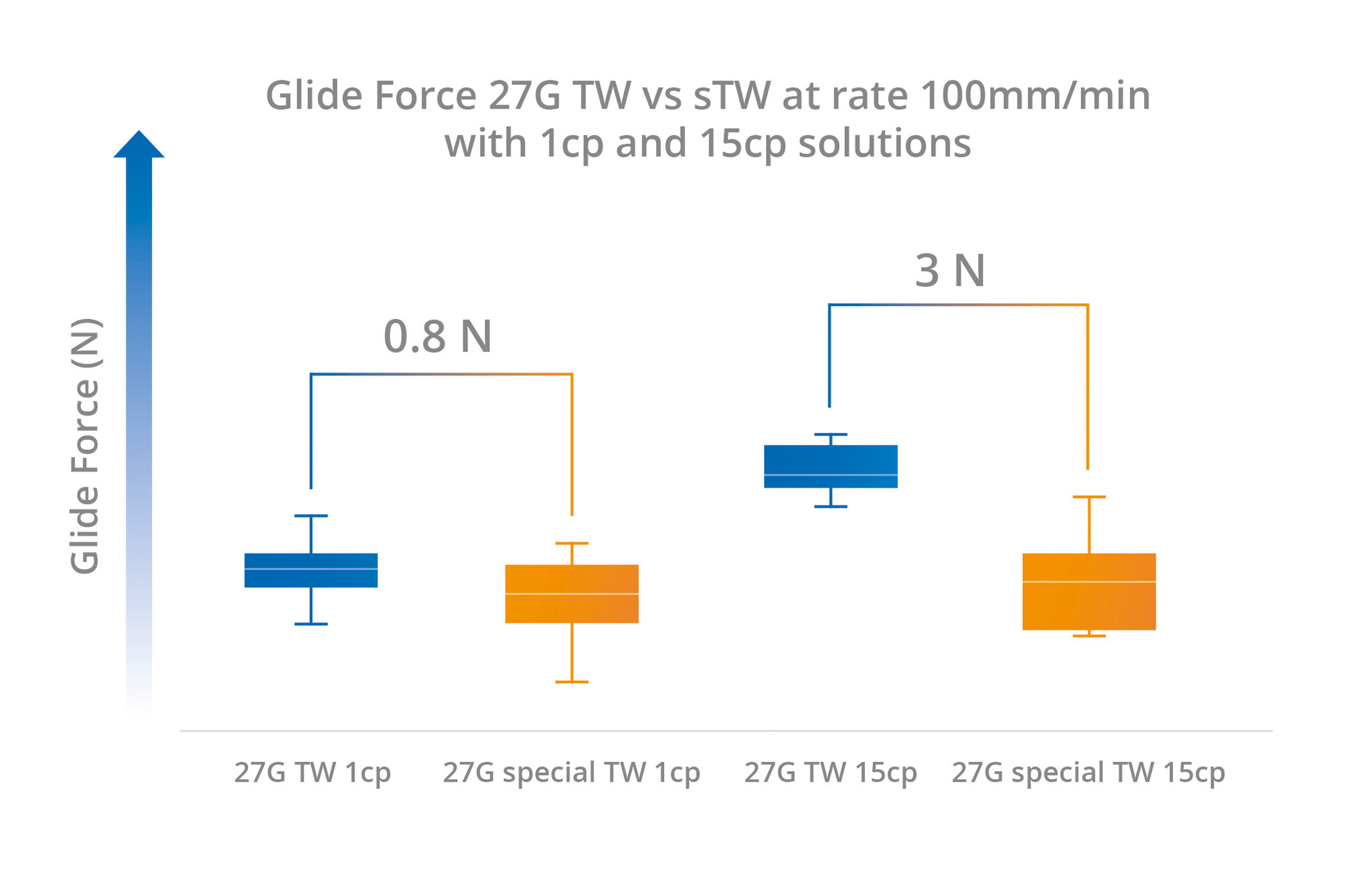

To analyze the comparative performance of the special Thin-Wall (sTW) needle against standard Thin-Wall (TW) needles, a series of tests were undertaken in-house, in our Technology Excellence Center.

As shown in the graphs, the sTW needle registers an improved gliding force compared to the standard thin-wall needle as the viscosity of the solution increases, thus confirming that the sTW needle optimizes the delivery of highly viscous drug formulations avoiding the use of bigger needles.

Find more on the product range and advantages of sTW needle