Our RTU Vials process enhances Sterility Assurance, minimizes contamination risks, and reduces capital investment by outsourcing washing and depyrogenation.

The Contamination Control Strategy (CCS) is crucial for demonstrating risk management to inspectors, with RTU packaging being a top solution to meet regulatory and market demands.

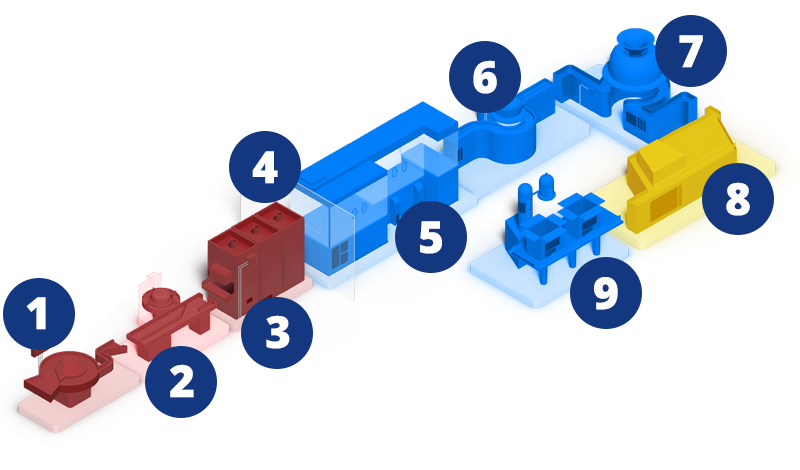

The conventional configuration of aseptic fill & finish operations generates well known risks that pharmaceutical companies need to manage.

Bulk aseptic filling process

Criticalities:

Glass-to-glass and glass-to-metal contact

Heat tunnel can increase the coefficient of friction on the outer surface of the vial

Wasted time on non-core activities

Time consuming format change

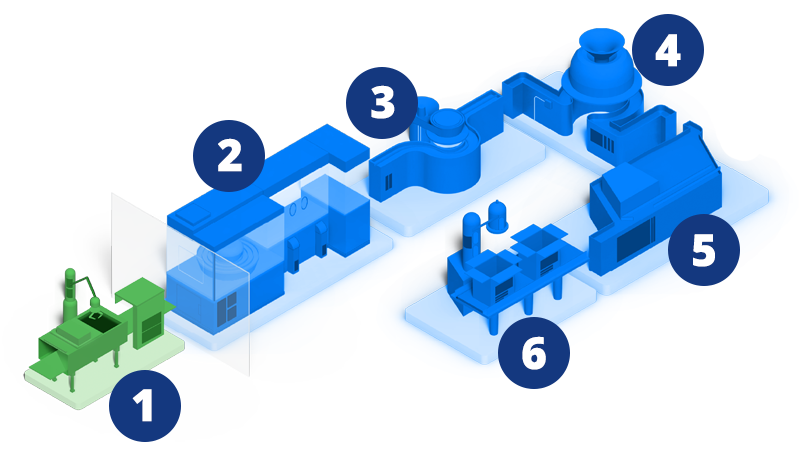

RTU aseptic filling process

The RTU aseptic filling process provides many benefits over conventional processes reducing the following risks:

Contamination due to glass particles

Rejections/market recalls caused by glass defects (waste of drug product)

Human errors on non-core activities

EZ-fill® offers a wide range of vial solutions to guarantee compatibility with low-speed and high-speed filling equipment. We offer Fina® EZ-fill® vials and LDP EZ-fill® vials.