Our thorough knowledge of the pharma industry’s manufacturing process and challenges

has motivated us to develop in-house capabilities to provide you with utmost quality.

All machinery from Stevanato Group are built on transport platforms and process modules. Their combination makes it possible to supply tailor-made equipment that meets your exact needs. Every device is different and every company has particular requirements: we are ready to deliver.

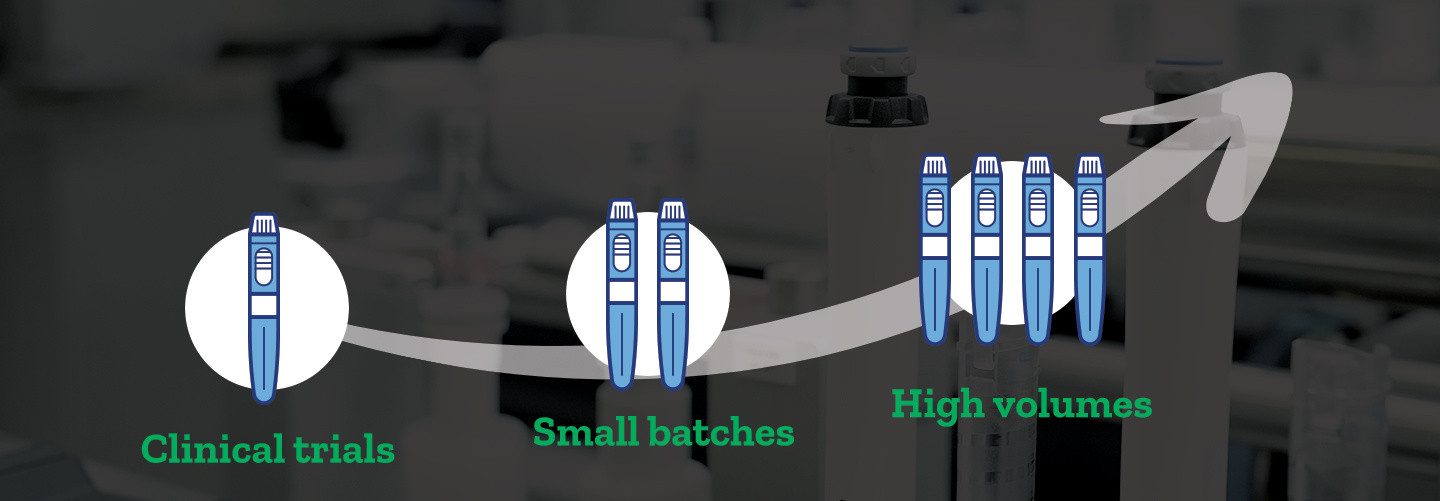

Scalability

Modular design is scalable, and it can be easily ramped up from small batches to large-scale production. Furthermore, it enables the transfer of technology from an automation level to the next, which reduces validation time

Flexibility

Modularity enables us to combine assembly, labelling and packaging lines on the same line with a single user-friendly control panel that manages all the processes.

Turnkey lines

Modularity enables us to combine assembly, labelling and packaging lines on the same line with a single user-friendly control panel that manages all the processes.

With a comprehensive portfolio and a 30-year expertise in medical device assembly, Stevanato Group offers a full range of flexible solutions tailored to satisfy the quality and productivity goals of pharma companies and contract manufacturers.

Manual or semi-automatic assembly of a wide variety of devices. Ideal for small production, it can process from 1 to 6ppm.

Application: Designed for the device development phase and to analyze process parameters (components processability, required forces, etc)

Flexibility: Fixtures are changeable in order to

handle different devices. Incline control features are available upon request

Designed to support you since the early stage of your development or assembly process.

Specifically designed for the production of pilot series and small quantities, this line is based on a linear, freely programmable indexing system.

Application: This line can analyze the production ability of the products and verify optimization points before building a high-volume production line.

Compliance: It has been designed for production in Cleanroom class 8, compliant with ISO14644.

Flexible platforms based on a linear transport system for complex assembly tasks. Our linear platforms can accommodate small-medium volumes and are the best-in-class choice for high-volume production, scalable up to 200ppm.

Application: sub-assembly and final assembly of a variety of devices, such as pen injectors, auto-injectors, inhalers, wearables, etc

Vertical (XTV) or horizontal (XTH) motion: our equipment is ready to fit into any production line or flow scheme, based on layout and request to integrate manual workstations.

One platform. Countless applications: a modular assembly platform that reduces dependence on risky forecasts and accommodates different formats and future capacity needs.