Reading Time: 2 minutes

Patient safety and product quality are priorities in pharma manufacturing processes.

With billions of injectable doses administered worldwide every year and strict safety guidelines regulating operations, the need for efficient, technologically advanced and highly accurate automatic inspection systems has increased dramatically.

Camera-based inspection techniques have gone through many improvements in the last 20 years, when entering the digital era. Automatic visual inspection offers several advantages, including process consistency, speed and cost-effectiveness. Let’s see how the main technologies available on the market can meet different needs.

Inspection machines featuring still cameras are suitable for small containers - such as ampoules, cartridges and vials of up to 30mm diameter – and they guarantee efficient detection of cosmetic defects and particles up to a size of 50µm. Containers are rotated at high speed and stopped in front of the camera, setting particles into motion by inertia. Modern software compensates for issues related to sensors and makes it possible to capture high-resolution images of the product. Opting for this solution drastically reduces maintenance costs, as all the inspection components are mounted in a fixed position.

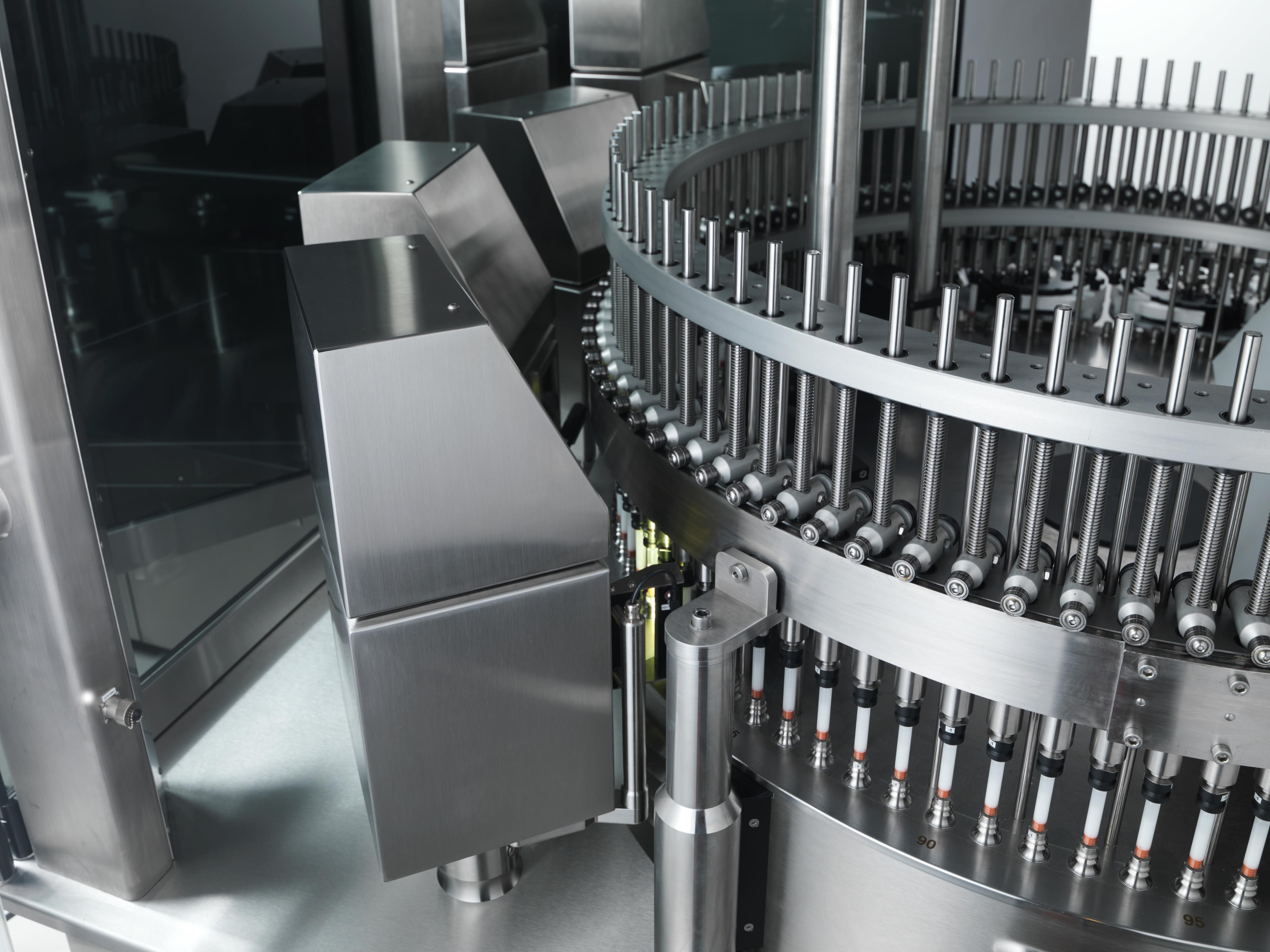

The introduction of a mirror in the machines a couple of decades ago was a significant innovation in the inspection process. It enables users to efficiently inspect containers up to 50-100ml capacity, detecting defects down to sizes of 20-30µm. Line-scan cameras frame the mirror positioned at the center of the carousel and, by reflection, the container, while remaining still. An even better solution, adopted by Stevanato Group, features a mirror for each inspection station: this makes it possible to acquire more images from different angles and to avoid reflection. Some ‘tricks’ make this inspection method particularly powerful. The interposition of a prism allows for additional controls, for example, crimping inspection with a bottom-up view or the identification of bubbles on the plunger surface. The application of 3D technology enables users to differentiate between particles inside and outside the container in highly viscous products, such as hyaluronic acid.

Automatic equipment with continuous motion technology is the best choice for large-size mold glass containers: customers benefit from the sensor resolution, as the camera is moving simultaneously with the container. With other methods, there is a risk of high false rejection rate the larger the container diameter is, because, after long use, the light source can get dirty and this can impact on the inspection process. On the other hand, tracking cameras ensure very low liquid perturbation and a limited false rejection rate.

Relying on proven technologies is of the utmost importance for high product quality and teaming up with the right partner is key to ensure patients’ safety and minimize product recalls. Stevanato Group has a wide-ranging expertise in inspection systems and can provide the right technology for different needs, offering the best-suited application from lab development to large-scale production.