カスタマイズされたフレキシブルかつスケーラブルな自動化システムを提供し、ペンインジェクターやオートインジェクターなどのドラッグデリバリーデバイスを正確に組み立てます

This platform breaking-through modularity and

scalability promise to turn things upside-down.

Discover how you can reduce CAPEX investments on

your device assembly equipment and get shorter time

to market, manufacturing different device formats, or

devices on the same line.

Efficiency

Each carrier has individual control curves to accelerate, brake, position and synchronize itself, according to operations performed on the machine. This has the benefit of minimizing the overall length and associated investment and operational costs thanks to cycle-time-optimized station layout.

Scalability

With modular design and simple extension, production lines can be designed and built with actual production needs and Capex restrictions in mind. You get fast time to market paired with already integrated ramp-up of production volumes for the future.

Flexibility

Capable of handling various elements with different sizes and shapes, the platform allows for multiple programs, which means shorter lead times and the production of components with different features on the same machine.

Compact footprint

Precise control of the carriers’ acceleration and deceleration is an important benefit as it helps

optimizing the processes operated on the line, such as vision inspection controls, printing or labeling, etc., thus reducing the need to implement further stations.

Sustainability

No dust or abrasion: our transport system significantly reduces the risk of contamination that comes attached with conventional beltand chain-type conveyors. Moreover, its operation is very silent and requires no special maintenance, which also makes our equipment an ideal solution for clean rooms.

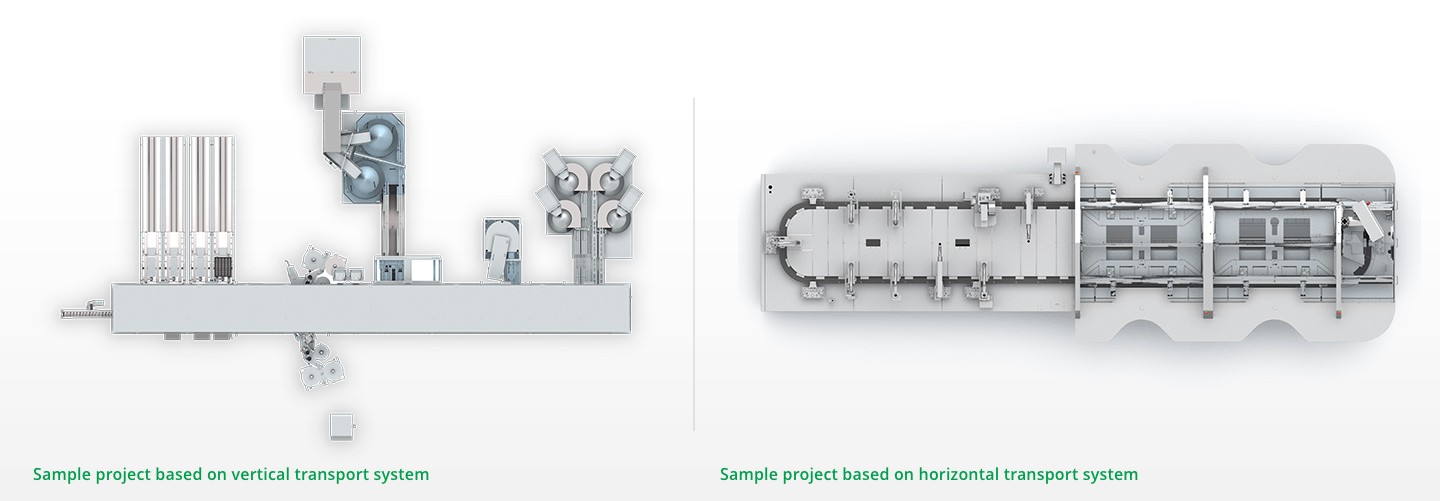

BasiQX platform is available with vertical (XTV) or horizontal (XTH) transport system. Check out here the main features of each version.

| XTV | XTH |

|

Servo driven solution |

Servo driven solution |

|

Inspections and other processes adapt to different cycle rates |

Inspections and other processes adapt to different cycle rates |

|

Freely configurable component infeed and outfeed systems |

Freely configurable component infeed and outfeed systems |

|

Possibility to integrate automatic change over |

Allows to integrate manual workstations with fully automatic equipment |

|

Maximum accessibility |

Suitable for limited sites’ footprint |

|

Long and slender machine layout |

More squared layout (wider and shorter) |

|

1 operator side |

2 operator sides |